![]() 116 E. 30th Street, Kansas City, MO 64108, USA.

116 E. 30th Street, Kansas City, MO 64108, USA.

![]() +1 (816) 7723095

+1 (816) 7723095

Vacuum packaging, a technique enabling to get rid of impurities, moisture and oxygen inside a container, leading to longer food preservation. It is an exceptional leap forward in food packaging.

The fundamental of vacuum chamber operation:

Vacuum machines create around the food a tight room, isolated from the external environment. By means of a pump, the air present in the room, as well as in the product packaging, is removed. This enables to remove from the packaging gases and impure particles which are present in the air, moisture and oxygen, a vital gas for man as well as for microorganisms such as bacteria and molds. Their proliferation is blocked and their metabolisms, i.e. fermentation, are inhibited. To ensure the effectiveness of such method and maintain vacuum over time, the packaging – either bag or bowl – must be properly sealed.

Small and compact for entry level vacuum packaging. Ideal for restaurant, butcher, laboratory and small business applications.

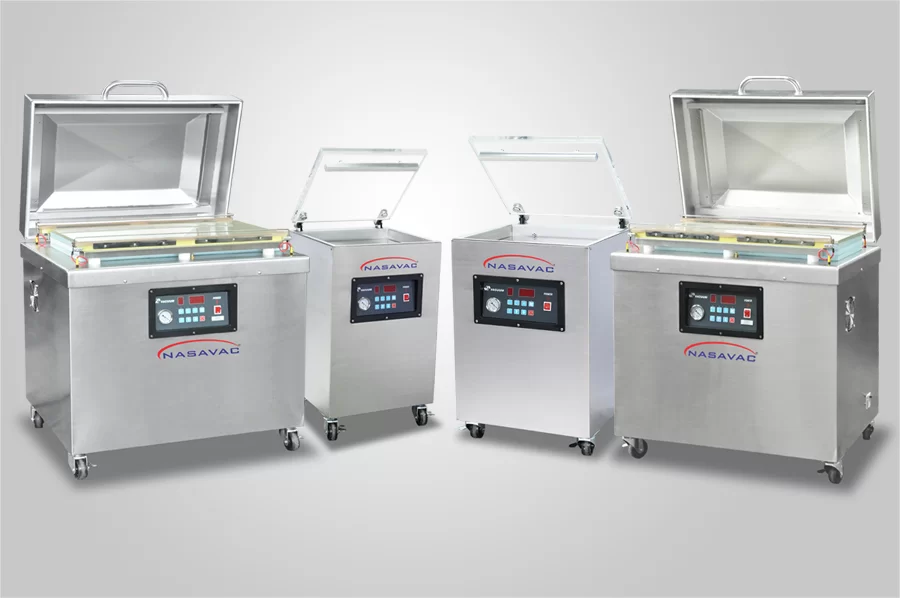

Versatile vacuum sealers with mobility, and heavy duty usage. Ideal for packing several pouches per cycle of large sized products.

The double chamber vacuum sealers have higher productivity, as bag loading and unloading can be done while working on the other chamber.

Inline belt type chamber vacuum sealer designed for small to medium products with high volume packaging application.

Design to prevent particle generation and oil contamination, ideally for cleanroom environment vacuum packaging.